Ospa vacuum filter systems operate fully automatically and reliably.

Corrosion-resistant

Ospa vacuum filter systems are made from polypropylene (PPh) with galvanized reinforcement.

The perfect solution for commercial swimming pools – powerful, economical, and energy-efficient.

An intelligent system solution that grows with its tasks: Ospa vacuum filter systems. This highly efficient and infinitely scalable solution for hygienic and smart filtration also saves space and resources. Wherever efficiency, fully automated operation, and space-saving installation are priorities, Ospa vacuum filter systems set the standard. See for yourself!

The core principle of Ospa’s pool filters is to remove as many impurities as possible through optimal filtration. The better a filter removes organic impurities, the less chemical water disinfection is required, enabling gentle water treatment.

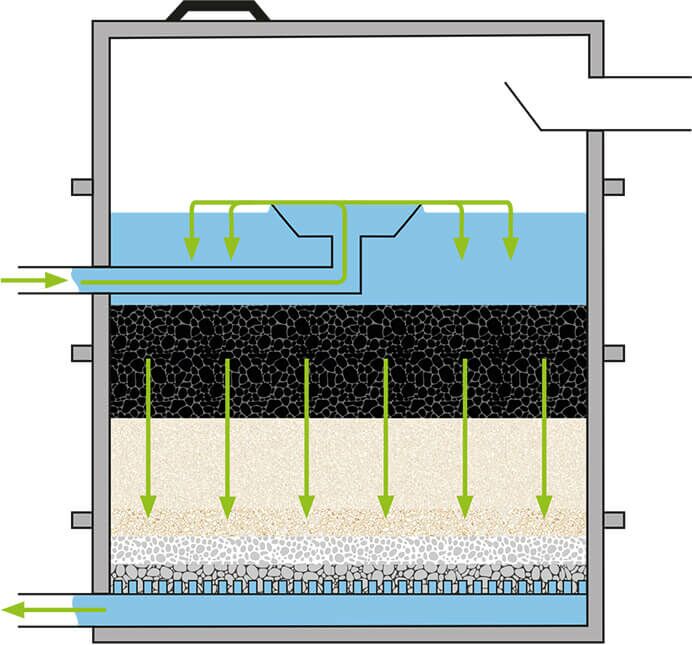

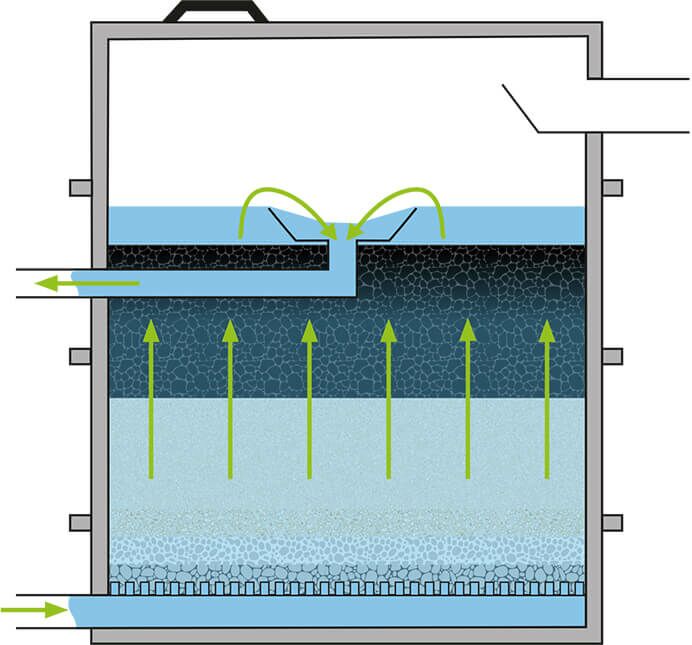

Ospa vacuum filters use filtration layers consisting of hydroantracite S with a grain size of 0.6 – 1.6 mm, filter quartz sand with a grain size of 0.4 – 0.8 mm, and supporting layers with varying grain sizes. The specialised Ospa hydroantracite S exhibits properties similar to activated carbon. This allows Ospa vacuum filters to reduce combined chlorine and other organic chlorine compounds, such as THM and AOX.

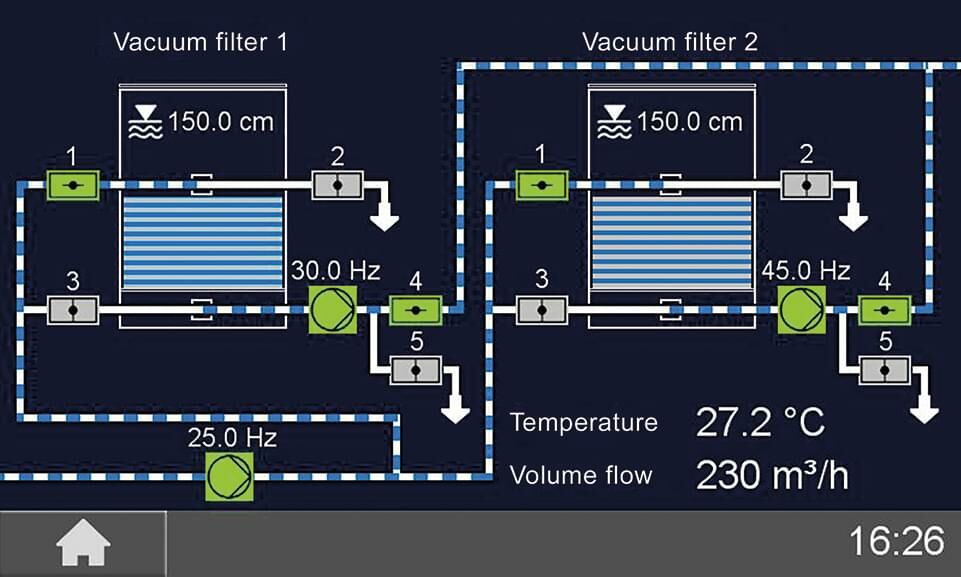

Ospa’s vacuum filter technology, powered by its unique BlueControl® filtration system, is significantly more energy-efficient than other solutions on the market. Additionally, it offers maximum convenience. Thanks to state-of-the-art control technology, Ospa vacuum filter systems operate fully automatically.

Energy efficiency works best when all components are optimally coordinated: Ospa offers a well-thought-out system technology and the expertise gained from over 65 years of research and development. All components of Ospa swimming pool technology are designed for energy-saving operation. This includes not only the filter but also the VSD-controlled raw water and filtrate pump. Thanks to the innovative BlueControl® control system, Ospa can completely eliminate the need for a separate backwash pump.

Ospa vacuum filter systems operate fully automatically and reliably.

Robust, durable, and also energy-efficient.

Reduced energy consumption, water-saving, and resource-efficient.

Ospa filter systems can be individually scaled to meet any requirement. Standard filter sizes can be found below.

Reduces operating, maintenance, and servicing costs.

Made of polypropylene (PPh) and galvanized reinforcement.

Ospa vacuum filter systems require up to 30% less space than comparable pressure filters.

Meets DIN 19605 and 19643 standards.

The fully automatic Ospa multi-layer vacuum filters use the suction filtration process.

The filter tanks are made of rectangular polypropylene: closed at the top, with a removable lid, a connection for a safety overflow into the water water balance tank, electronic level monitoring, sight glasses for visual inspection of filter operation and layer separation during filter backwashing, a side manhole, and a maintenance opening below the nozzle plate. Raw water inflow and sludge water outflow systems ensure DIN-compliant, pressure-free filtration and backwashing operations. These systems provide uniform tank flow and consistent removal of debris across the entire filter surface without discharging filter material, even at DIN 19643 backwash speeds of 50 to 55 m/h.

The Ospa multi-layer suction filters feature a nozzle plate topped with supporting and filtering layers.

The filtering layers comply with DIN 19643 and consist of 400 mm of quartz sand (grain size 0.4 – 0.8 mm) and 400 mm of hydroantracite S (grain size 0.6 – 1.6 mm), with properties similar to activated carbon. This enables them to reduce combined chlorine and other organic chlorine compounds, such as THM and AOX, that can be adsorbed by activated carbon.

Electronically controlled pneumatic valves enable fully automatic filter backwashing and channel discharge of the first filtrate. In the event of power or compressed air failure, the valves close automatically.

| Model | Filter area | Filtration | Backwashing | Dimensions |

|---|---|---|---|---|

| UD 200 | 2.0 m² | 60 m³/h | 110 m³/h | 1.7 x 1.7 x 2.5 m |

| UD 250 | 2.5 m² | 75 m³/h | 138 m³/h | 1.8 x 1.9 x 2.5 m |

| UD 280 | 2.8 m² | 84 m³/h | 154 m³/h | 1.8 x 2.1 x 2.5 m |

| UD 300 | 3.0 m² | 90 m³/h | 165 m³/h | 1.8 x 2.2 x 2.5 m |

| UD 380 | 3.8 m² | 114 m³/h | 209 m³/h | 2.2 x 2.2 x 2.5 m |

| UD 400 | 4.0 m² | 120 m³/h | 220 m³/h | 2.2 x 2.3 x 2.5 m |

| UD 450 | 4.5 m² | 135 m³/h | 248 m³/h | 2.2 x 2.6 x 2.5 m |

| UD 500 | 5.1 m² | 153 m³/h | 281 m³/h | 2.3 x 2.7 x 2.5 m |

Additional sizes available upon request